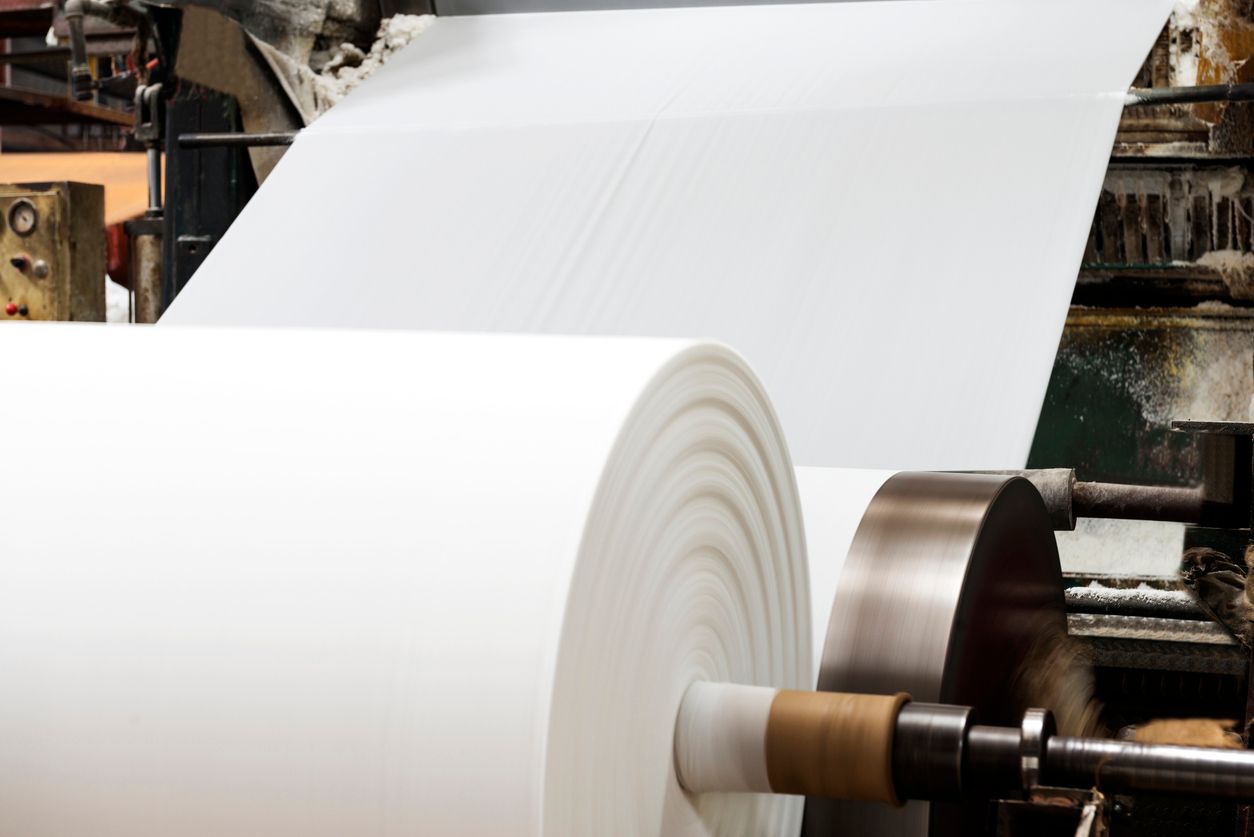

Smooth, Clog-Free Pumping for Pulp, Slurry, and Coating Fluids

From recycled fiber and kaolin slurry to chemical additives and wastewater, Tesla Disk Pumps™ are built to reduce downtime, preserve flow integrity, and fit tight industrial layouts.

Handling Slurry, Fiber, and Coating Fluids Without Clogging or Shear

Tesla’s vertical and inline options fit tight industrial layouts while preserving flow quality. Perfect for coating processes, reclaim systems, and chemical treatment steps in paper manufacturing.

Common Fluids in Pulp & Paper Applications:

- Recycled fiber slurry and deinked stock

- Kaolin and titanium dioxide coating mixtures

- Starch, retention aids, and wet-end chemicals

- Graywater and wastewater with suspended solids

- Sludge, scale, and reclaimed process water

Industry Challenges — and How Tesla Disk Pumps Solve Them

In pulp and paper production, pumping systems face a unique mix of mechanical, chemical, and space-related challenges. From long fiber strands and abrasive coatings to limited floor space in aging facilities, Tesla Disk Pumps™ are engineered to deliver dependable performance where impeller pumps fall short.

Space-constrained facilities

Paper mills often have compact layouts with limited room for pump installations. Tesla Disk Pumps offer vertical and inline configurations that fit seamlessly into tight footprints without sacrificing performance.

Abrasive and fibrous slurries

Pulp and reclaim systems contain fibers, fillers, and grit that quickly wear down traditional impeller pumps. The Tesla Disk Pump’s non-impeller rotor reduces erosion and clogging, extending pump life and reliability.

Consistent flow for coating

Paper coating processes demand uniform, pulsation-free delivery of starches, pigments, and additives. Disk pumps provide smooth laminar flow that ensures consistent coating application and product quality.

Chemical treatment compatibility

Bleaching, sizing, and water treatment require handling harsh chemicals. Tesla Disk Pumps are available in corrosion-resistant alloys to withstand caustics, acids, and oxidizers.

Application Highlights Across Food and Beverage Processing

From the drill site to the refinery, Tesla Disk Pumps™ support critical oil and gas processes at every stage. Whether it’s moving thick slurries, protecting delicate catalysts, or handling gas-laden streams, our pumps are built to perform—no matter where they’re installed.

| Application Area | Benefits | How Tesla Pumps Excel |

|---|---|---|

| Coating Processes | Consistent, uniform flow for coating solutions | Laminar, pulse-free delivery enhances product quality |

| Reclaim Systems | Reliable handling of fibrous and abrasive slurries | Non-clogging rotor passes fibers and grit without wear |

| Bleaching & Chemical Treatment | Withstand caustics and oxidizers | Corrosion-resistant materials extend service life |

| Water & Effluent Handling | Manage solids-laden treatment streams | Dead-head and dry-run safe for variable flows |

| Inline/Vertical Installs | Save space in crowded plant environments | Compact designs fit where conventional pumps cannot |

Why Tesla Disk Pumps Stand Apart

Vertical and inline configurations maximize space efficiency.

Non-clogging, shear-free design handles fibrous pulp and abrasive fillers.

Corrosion-resistant alloys support chemical treatment applications.

Smooth laminar flow ensures coating uniformity and reduces waste.

Dry-run and dead-head safe to handle variable reclaim and treatment flows.

Extended equipment life reduces downtime and maintenance costs.

Real-World Impact

Tesla Disk Pumps™ don’t just perform better in theory—they make a measurable difference in the field. By reducing maintenance needs and minimizing downtime, they help operators lower costs and keep production moving. Whether it’s fewer seal failures or improved flow in difficult conditions, these pumps deliver real results in real-world operations

Find Your Pump Configuration

Jump to the Tesla Disk Pump™ solution that best fits your application:

Ready to Optimize Your Pulp and Paper Operations?

From coating to reclaim systems, Tesla Disk Pumps™ deliver the flow quality, reliability, and flexibility that modern paper mills demand. Compact by design. Reliable under tough conditions. Engineered for long-lasting performance.

Contact us today to discuss your pulp, coating, or chemical handling needs — and let us configure the right Tesla Disk Pump solution for your operation.