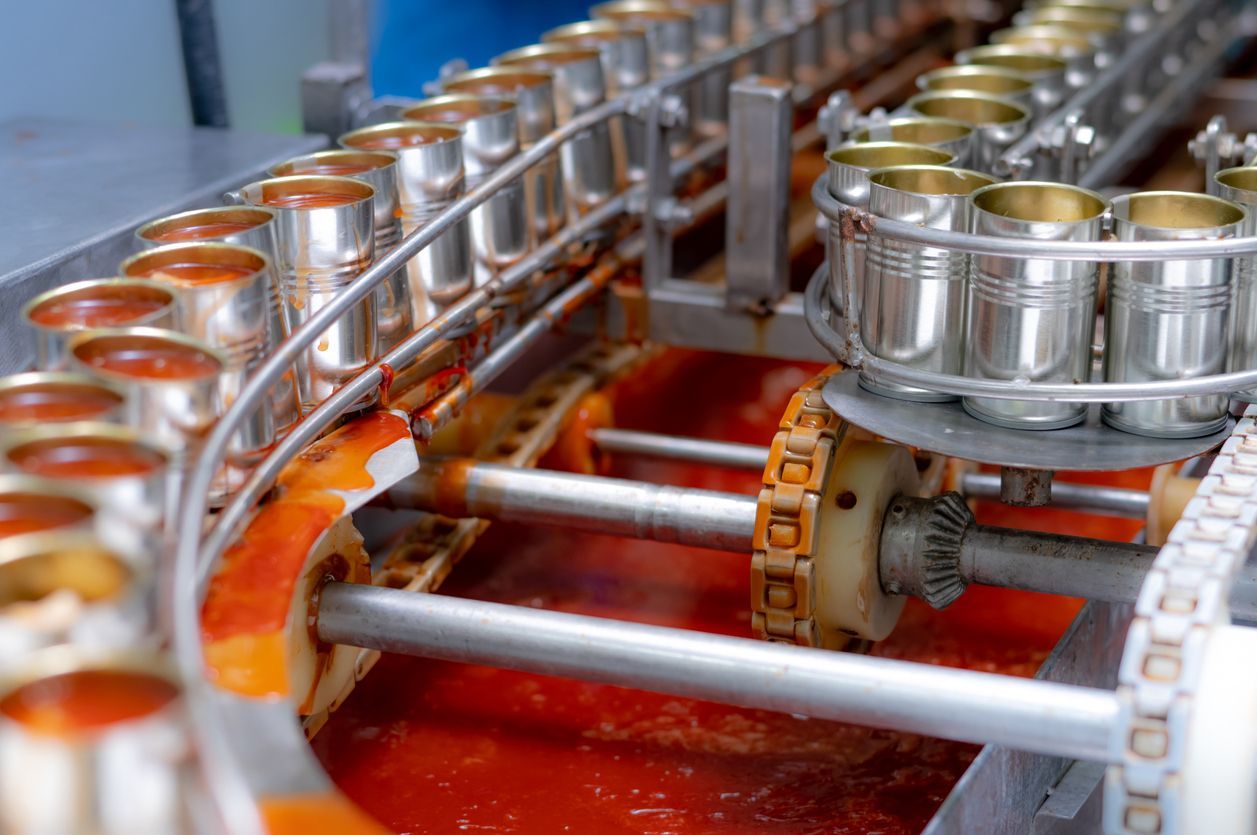

Pumping Solutions for Food, Beverage, and Ingredient Handling

Move sauces, oils, slurries, and fragile food products without shear, contamination, or costly downtime. Tesla Disk Pumps™ preserve product quality at every step.

Protecting Product Quality, Preserving System Uptime

Ideal for sauces, oils, dairy, and beverage bases, Tesla Disk Pumps™ eliminate shear damage, foaming, or contamination. The smooth laminar flow preserves product quality while reducing cleaning cycles and process waste.

Common Media We Handle in Food & Beverage:

- Sauces, salsas, dressings, and condiments

- Yogurt, creams, dairy mixes, and plant-based milks

- Beverage bases, syrups, and sugar solutions

- Slurries with pulp, seeds, or suspended solids

- Cooking and frying oils

- Fermentation byproducts, mash, and yeast cultures

Industry Challenges — and How Tesla Disk Pumps Solve Them

Food and beverage processors face a unique balancing act: maintaining product integrity while meeting rigorous sanitation and uptime demands. Tesla Disk Pumps™ are designed to support both—delivering smooth, non-shearing flow with fewer parts to clean and replace.

Here’s how we help you solve the most common pumping problems in food production environments:

Product integrity

Many food and beverage products are sensitive to shear, agitation, or aeration. Conventional impellers cause foaming, product degradation, or separation. Tesla Disk Pumps use a laminar, low-shear flow that maintains flavor, texture, and consistency.

Cleanliness and sanitation

Processing equipment must meet strict hygiene requirements. Tesla Disk Pumps are designed with clean-in-place (CIP) and sanitize-in-place (SIP) compatibility, minimizing downtime between production runs

Foaming and entrained air

From dairy to sauces, entrained air causes waste and quality issues. The disk rotor design moves fluids smoothly without vortexing or frothing.

Equipment wear and maintenance

High-viscosity or particulate-laden foods damage conventional pumps and increase cleaning time. Tesla Disk Pumps reduce wear, extend seal life, and minimize process interruptions.

Application Highlights Across Food and Beverage Processing

From the drill site to the refinery, Tesla Disk Pumps™ support critical oil and gas processes at every stage. Whether it’s moving thick slurries, protecting delicate catalysts, or handling gas-laden streams, our pumps are built to perform—no matter where they’re installed.

| Application Area | Benefits | How Tesla Pumps Excel |

|---|---|---|

| Sauces & Condiments | Preserve viscosity and mouthfeel | Low-shear flow prevents emulsification or separation |

| Dairy & Milk Products | Avoid foaming and denaturing proteins | Smooth laminar transfer protects delicate products |

| Oils & Fats | Gentle handling of viscous materials | Non-clogging design manages both light and heavy oils |

| Beverage Bases & Juices | Maintain clarity and flavor integrity | Prevents aeration, contamination, and shear damage |

| Particulate-Laden Products | Safely transfers products with seeds, pulp, or spices | Passes solids without clogging or damaging product |

| CIP/SIP Cycles | Faster, more efficient cleaning | Reduced residue build-up means fewer cleaning cycles and less downtime |

Why Tesla Disk Pumps Stand Apart

Shear-free pumping protects texture, flavor, and appearance.

Laminar, smooth flow prevents foaming, air entrainment, and product loss.

Hygienic construction with stainless steel options supports food safety compliance.

CIP/SIP compatible design reduces downtime and cleaning costs.

Handles particulates without damage for products with seeds, pulp, or inclusions.

Reduces waste by minimizing residue left behind in lines and equipment.

Real-World Impact

Tesla Disk Pumps™ don’t just perform better in theory—they make a measurable difference in the field. By reducing maintenance needs and minimizing downtime, they help operators lower costs and keep production moving. Whether it’s fewer seal failures or improved flow in difficult conditions, these pumps deliver real results in real-world operations

Find Your Pump Configuration

Jump to the Tesla Disk Pump™ solution that best fits your application:

Ready to Improve Your Food and Beverage Processing?

From dairy to sauces, Tesla Disk Pumps™ provide the reliability, hygiene, and performance that modern food and beverage plants demand. Built for quality, engineered for efficiency.

Contact us today to discuss your product and processing requirements — and let us tailor the right Tesla Disk Pump solution for your facility.