Find the Right Pump for Your Process

Explore Tesla Disk Pumps™ by configuration, installation type, and performance capabilities. Built to solve challenges impeller pumps can’t.

Find Your Pump Configuration

Jump to the Tesla Disk Pump™ solution that best fits your application:

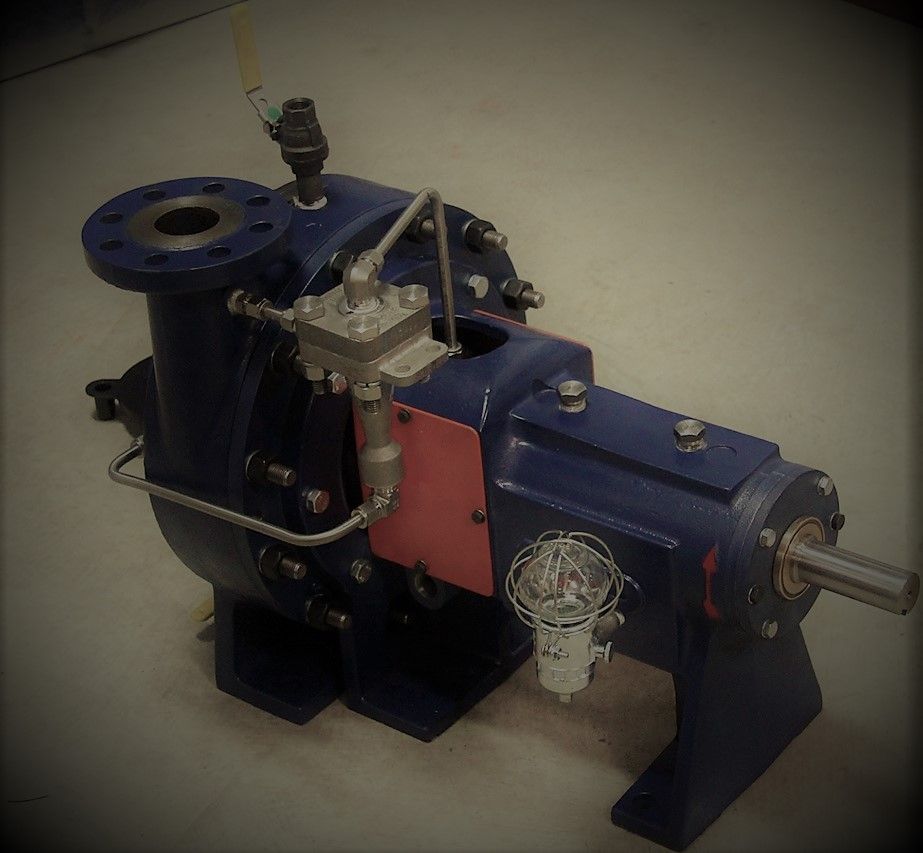

Horizontal Pumps

Heavy-duty, floor-mounted solutions for high-volume industrial operations.

Tesla Disk Pumps™ in horizontal configuration are built to handle some of the harshest conditions in fluid management. With no impellers and fewer moving parts, they excel in transferring abrasive, corrosive, or viscous materials while minimizing wear and maintenance.

Key Features:

Modular bearing frame for simplified service and extended operational life

Consistent laminar flow prevents clogging and shearing

Operates under low NPSHr conditions—ideal for challenging suction systems

Configurable for packed or mechanical seals

Common Applications:

Sludge and slurry transfer in wastewater treatment

Chemical and polymer pumping in industrial processing

Thick fluids and recycled materials in mining and plastics

Vertical Inline Pumps

Space-saving performance for confined installations and inline systems.

Tesla’s Vertical Inline Pumps are ideal for facilities where floor space is limited but performance can’t be compromised. These pumps provide all the benefits of our disk rotor technology—shear-free, non-clogging, low-maintenance flow—in a vertically aligned, compact footprint.

Key Features:

Inline design reduces piping complexity and system footprint

Available for wet-pit or dry-pit installations

Laminar flow minimizes turbulence, product degradation, and energy loss

Durable construction with optional corrosion-resistant materials

Common Applications:

Municipal and industrial water treatment in vaults or basements

Paper, pulp, and slurry circulation with suspended solids

Retrofits and compact skids where space and alignment are critical

Submersible Pumps

Fully submersible pumping solutions for containment, sump, and flooded systems.

Tesla Disk Pumps™ in submersible configurations are engineered for applications where complete immersion is required. Whether in tanks, basins, or corrosive fluid wells, these pumps provide smooth, non-shearing flow without the need for priming or complex suction setups.

Key Features:

Operates while fully submerged—no external suction needed

Resistant to corrosive and abrasive media with premium materials

Self-cleaning internal geometry minimizes clogging and buildup

Compatible with electric or hydraulic submersible drives

Common Applications:

Tank drainage and collection pits in industrial plants

Marine or offshore containment systems exposed to saltwater or sludge

Emergency or overflow pumping where rapid deployment is required

Specialty Configurations

Custom-engineered pumps for high-pressure, regulatory, and extreme-duty applications.

When your system demands more than a standard setup, Tesla Disk Pumps™ delivers precision-engineered solutions tailored to your environment. From API 610 compliance to progressive cavity pump replacements, our specialty configurations are built to meet performance and reliability standards in the most rigorous operating conditions.

Configuration Options

API 610 Process Pumps – Designed for petroleum and chemical industry compliance

Dry-Pit Emulsion Units – Ideal for mixing and recirculating viscous or multiphase fluids

Hydraulic Drive Configurations – Perfect for mobile or remote systems where electrical supply is limited

High-Pressure Pumps – Built for up to 3750+ PSI with reinforced materials and seal assemblies

Progressive Cavity Replacements – Upgrade aging systems without sacrificing flow quality or solids handling

Material & Seal Flexibility:

Available in CD4, ASTM A532, and 316 Stainless Steel

Packed and mechanical seal options based on fluid type and pressure demands

Fully customizable ports, drive mounts, and bearing frames

Still Not Sure Which Pump Fits Your Process?

We’re here to help. Whether you're upgrading an existing system or designing a new one, our engineers can help you select the right Tesla Disk Pump™ based on your fluid type, flow requirements, and operating conditions.